In the past two years, what did the chip distribution industry have experienced? Jiang Yang was evaluated with an economic academic term "Davis Double Kill". The so -called "Davis Double Kill", it can be explained in popular explanation -when a company's performance decreases, the income per share decreases or decreases, the valuation given by the market has also decreased, and the stock price has obtained a multiplier.

Compared with the impact of the new crown epidemic, for the global semiconductor industry, in the past three years, the impact of the electronic manufacturing supply chain is undoubtedly more worthy of everyone's attention. Beginning in June 2022, if 12 months as a cycle, look at the hottest keywords in the semiconductor industry, the first keyword is "production capacity", the second keyword is "price increase", the third The keyword is "cutting orders". The dramatic changes in supply and demand relationships have undergone profound changes in promoting the global semiconductor industry chain. With the fermentation of events such as Sino -US trade frictions, chip disconnection and new crown epidemic, the global chip supply chain problem has been upgraded to the issue of China's manufacturing lifeline.

In terms of supply, due to the deformed development of the industry, the shortage of chip supply in the field of medical, automobiles, and new energy in the field of medical, automobiles, and new energy has also been fluctuated.

In terms of demand, with the raging global crown epidemic, the terminal product market under the reaches of electronic components has been greatly impacted. Beginning in the second half of 2022, due to the weak consumer electronics market, the market market in the upstream chip market has risen sharply, and the cutting orders and destocking have troubled the entire supply chain.

"The chip distribution industry has encountered 'Davis Double Kills'. The depreciation of the inventory in the hands of the distributors is far more cruel than everyone imagined. As a distributor of the middle dealer of the supply chain, especially for independent distributors, we The pressure on the shoulders is self -evident. Once the company's prediction error and the situation of the influence of funds will face the risk of bankruptcy. "Jiang Yang commented.

Q3 Some positive signals have been released

In the post -epidemic era, the global economic period is downward, the transfer of industrial layout and geopolitical factors continues to affect the industrial chain and ecology of global semiconductors. Due to the longer destocking cycle of all aspects of the supply chain than expected, the industry's optimistic outlook on "the second half of the year is expected to recover" has not arrived as scheduled.

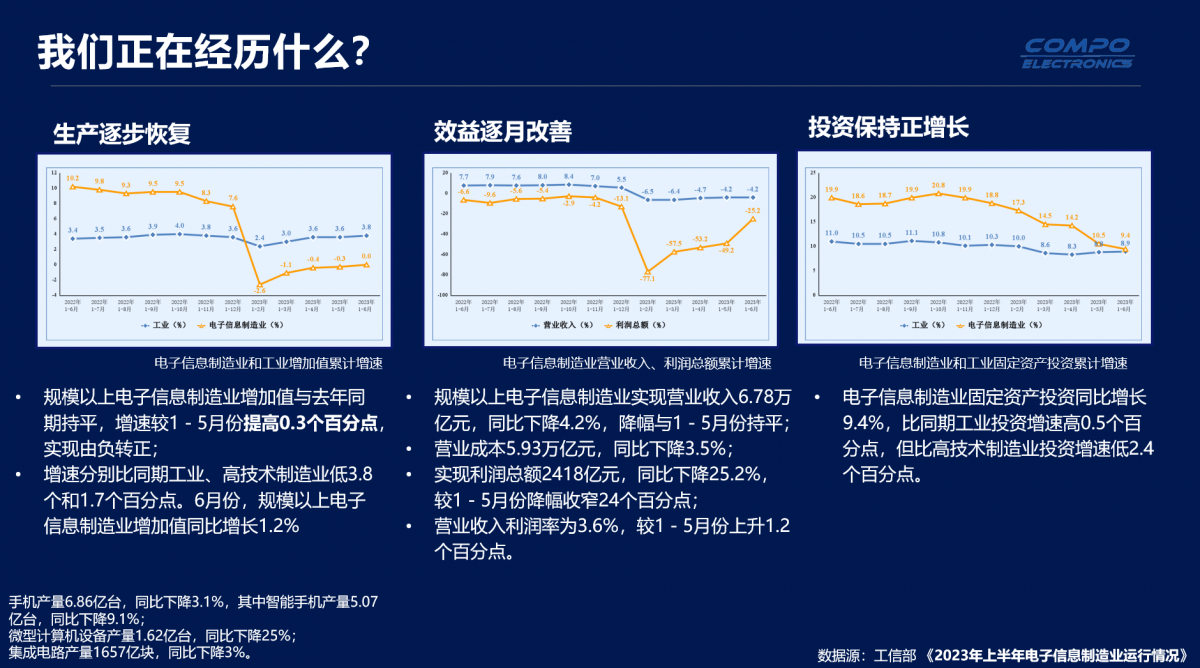

Since the second half of 2023, some positive signals are being released. According to data from the Ministry of Industry and Information Technology of China, the production index of the domestic manufacturing industry has improved, and the downward decline has narrowed. At the macroeconomic level, although the global economic index hit a new low, the downward trend has rebounded since August. At the same time, the decline in the domestic electronic information manufacturing industry is also narrowing, the production index continues to resume better, export decline continues to narrow, and investment has become stable.

In addition, the production and sales data of the semiconductor industry also rebounded. According to SIA statistics, in August of this year, sales in the global semiconductor industry increased by 1.9%month -on -month, which is already the sixth consecutive month of global semiconductor sales.

Although the added value of the domestic electronic information manufacturing industry and industry, as well as the negative growth of operating income and profit, the index has been slowly recovering since August, and its decline has also narrowed. At the same time, the investment in fixed assets of manufacturing still maintained a year -on -year growth rate of 9.4%. China's semiconductor industry has reached a new high (year -on -year increase of 21%), and the amount of semiconductor import and export has also improved.

In addition to the above positive signals, the time of the chip is gradually shortening, and the delivery process has gradually stabilized. The chip inventory has improved in the development of twists and turns. The situation of rebound. Looking forward to Q4 in 2023, the overall demand will become a key factor in the global semiconductor turning. Electric vehicles, photovoltaic, and energy storage are still the driving force for continuous leading the development of the industry.

Do these good signals mean that the signal of recovery has arrived?

"I personally think that there are still many uncertainty." Jiang Yang pointed out that in the era of stock, even if the load is load, it is necessary to move forward. In such a period of cycle and growth resonance, the security and toughness of the supply chain still need to reinforce the supply chain. The distributor continues to pay attention to "building a benign and sustainable, recirculable ecosystem and reasonable ecological layout", so as to effectively cope with various uncertain factors.

"Supply Chain+" ecology co -construction close business chain

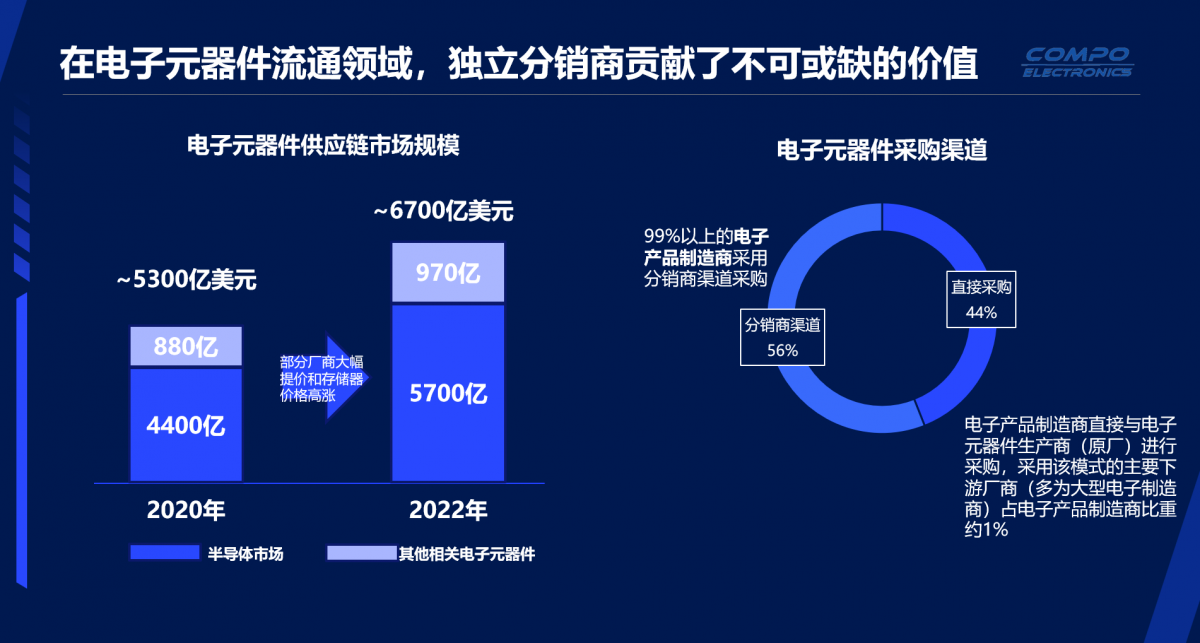

In the field of circulation of electronic components, distributors have an indispensable value. The size of the global electronic component supply chain market has increased from US $ 530 billion in 2020 to US $ 670 billion in 2022, of which more than 56%of the amount contributed by distributor channels. Electronic product manufacturers with more than 99%of the terminals use distributor channels to purchase components. Therefore, distributors play an extremely important role in the field of electronic components.

"'We are committed to making the value of technology benefit more people', I personally appreciate and agree with this sentence," Jiang Yang commented on the mission and vision of global distributor Ai Rui Electronics, "This should also be the entire distribution industry The mission and vision, it reveals the value direction and core competitiveness of the new generation of outstanding distributors. "

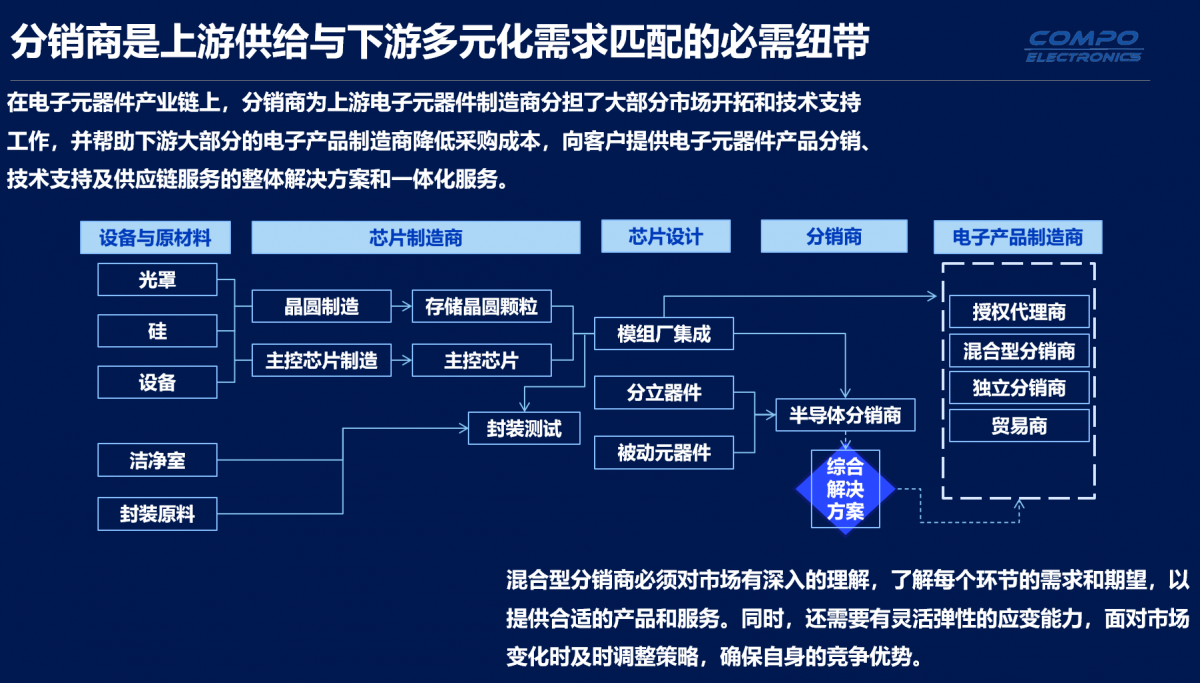

In addition to warehousing, distribution, and capital chain services, distributors are also the necessary links for upstream supply and downstream diversified demand matching. Experienced electronic component distributors can help the original factory to complete the work of market development, product promotion and technical support. It can also help downstream manufacturers reduce product development cycles and save product development costs for them.

Due to the rich customer resources of the distributor, it can also help the original and downstream companies to obtain more accurate market conditions forecast. Therefore, distributors must have a deep understanding of the market, understand the needs and expectations of each link, and think that customers provide suitable products and services. In addition, the distributors must also have the ability of flexibility and flexibility to respond to the market's time changes, and adjust their strategies in a timely manner to maintain their competitive advantages.

The forms of distributors include authorized distributors, independent distributors, and mixed distributors and trade distributors that take into account the above two forms. Different forms of distributors can be tacitly cooperated and divided into work. For example, they have different points such as helping customers from 0, specializing in large customers, providing spot, and so on. , Jointly promote the benign ecology of the entire supply chain to ensure the continuous operation of the entire industry.

With the further development of the semiconductor industry, new requirements have also been put on channels, and distributors can no longer only stay in the role of supply chain lubricant. Jiang Yang said that today's distributors have assumed the composite role of incubators, boosters, reservoirs, and lubricants. "Build an ecological structure of 'supply chain+', including extending to the upper and lower reaches of the industrial chain, creating an innovative business model, and the advancement of the service system.

Specifically, some distributors choose to extend upstream and transform into the original factory. For example, Well shares, it uses its own distribution business, agents more product types, master more market information, customer groups and product applications to help the company's semiconductor business rapidly develop.

It is worth noting that the "supply chain+" ecology is based on the supply chain, connecting the industrial chain, circulation chain, capital chain, and blockchain, forming a stable and closed -loop ecosystem with mutual support and support. , To form an ecological model of "chain chain, chain solid chain "-" supply chain+circulation chain "ecology includes a new type of e -commerce distribution model, and there are also some mature circulation platforms. Fields, for example, JD.com launched the JD electronic component platform; the ecological opening of the "Industrial Chain+Capital Chain" includes key peripheral participation elements including customs, taxation, financing, foreign exchange; The method of algorithms can be used to resolve the uncertainty in the complex system.

In the dispute over local components, everyone is also thinking about "how to expand the layout of business in depth and enhance their core competitiveness, so that after the overall market retreat, it can still maintain steady growth." This requires to maintain its own value by enriching its own ability. In addition to the ability to sell goods, local distributors also need to further establish a diversified supply chain, optimize the service experience, continue to tap high -quality customers, increase the depth in technical services Essence

On the one hand, as the ability to extend as the original factory, in addition to FAE, in turn, it can also promote the upgrade and technological innovation with the downstream terminals and originals; on the other hand, to integrate resources as a supplier of serving customers. Provide customers with comprehensive solutions.

By establishing a strategic partnership, we will further deepen the stickiness with customers. The distributors must share information sharing and build an open ecosystem together. The "supply chain+" ecology is actually a value ecological network composed of all participating entities in the supply chain operation. Through division of labor and cooperation with each other, they jointly create value, and finally realize the efficient operation of the entire industrial chain supply chain. The participation subject of the entire supply chain is not only a product provider, but also a participant in the process service. The design and procurement of the upstream end, the processing, distribution, commodity inspection, financing, etc. of the middle and lower reaches, they are highly concentrated in the overall framework and jointly build together A complete and close business chain.

How to build an ecological system capabilities?

The core of the distributor to build its own ecosystem is "strengthening collaborative management, and through the relationship between the relationship between the nodes of the supply chain, the seamless connection and coordinated operation of logistics, information flow, capital flow, and business flow." For example, in terms of digitalization, by building databases, using customer portraits, and purchasing behavior analysis and other data to empower market analysis, predict the market prosperity index, so as to help upstream and downstream companies make scientific decision -making basis and optimize resource allocation.

At present, China has a relatively mature system in digitalization. Local component distributors have also begun a digital value -added layout. Jiang Yang believes that in the process of digitalization of component supply chain, the e -commerce distribution model dominated by transaction services is not enough to cover the electronic manufacturing industry to improve the supply chain and strengthen the needs of coordinated manufacturing efficiency. The depth service level of the chain interconnection is also the comprehensive penetration ability that has not extended to the upstream and downstream. Therefore, the digitalization of the supply chain must make full use of the data potential of the ecological platform, integrate industrial resources on the basis of win -win cooperation, and comprehensively promote the improvement of the entire supply chain efficiency.

Internal enterprises must also comprehensively improve the ability of comprehensive ecology, knowledge acquisition ability, and common evolution ability. They can establish new collaborative ability and partnership ability through cooperation within the enterprise and the industry partners. Training and other methods continue to develop new partners. According to the changes in the market environment, we will continuously review and evaluate their business practice and strategy to maintain the toughness of the supply chain operation, and carry out the ability to reshape and reflectively control in the supply chain.

Article Source: International E -commerce

Address: Block 2, No. 70, Yaofeng West Road, Wuzhong District, Suzhou City, Jiangsu Province

Tel: 0512-82285066

Email: sales@kegasia.com

Please contact us

WeChat official account

Copyright © Suzhou KEG Industrial Co., Ltd. All right reserved ICP NO: Technical support:Web design